Substation Automation

System

Digital Substation Automation Operation System

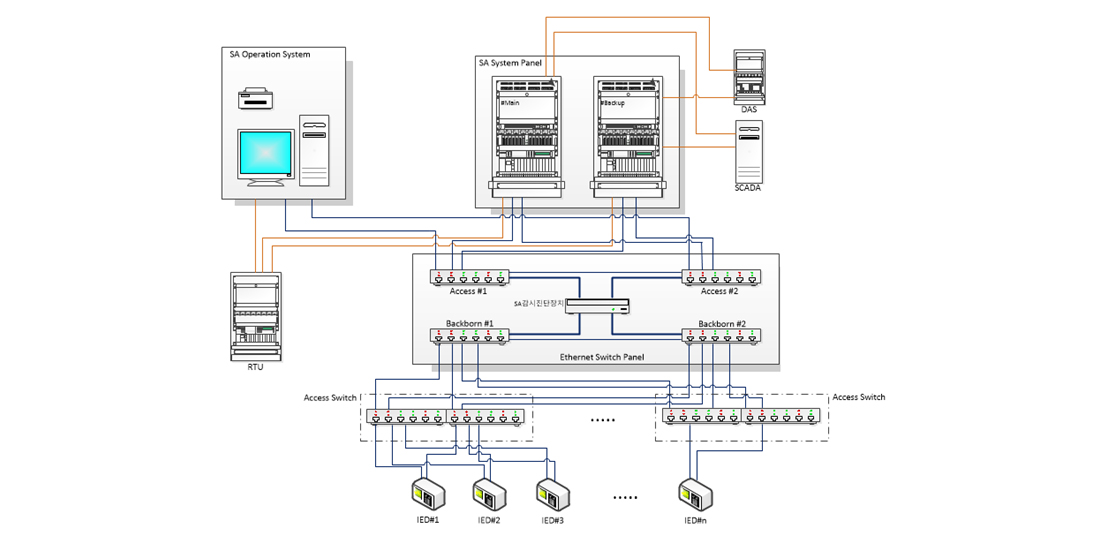

Digital Substation Automation Operation System is HMI(Human Machine Interface) system which provides operating information on each facility in the IEC 61850-based SA (Substation Automation) digital substation to the operator.

Main components

- SA operating device to communicate with IED devices in the substation by using IEC 61850, provide operating information and status information of each facility in the substation received from aforementioned devices to the operator, and also serve a role to transmit the facility control to IED when it is done by the operator

- Information connecting device equipped with IEC 61850 and DNP (Distributed Network Protocol) communicating function, connect IED and RTU in the substation by using aforementioned two communication functions, and connecting them to SCADA system with operating information or status information of each facility in the substation

- SA monitoring and diagnosis device to save and analyze all the communication data connected to IEC 61850 communication network on a real-time basis, provide communication data before and after the breakdown or abnormal conditions of electronic power facility, and monitor or diagnose the communication system in the substation

System configuration and explanation

1. SA operation device

As a device to provide operator interface on SA electronic power facility, It calculates operating information data from field devices such as IED and RTU while processing database and showing acquired data and event history to the screen for the operators. It calculates operating information as data from devices in the field as received from IED and RTU, while performing to process database and showing acquired data and event history to the screen so that the operator can recognize them.

2. Information connecting device

This device acquires and processes operating information of electronic power facilities in the substation. Receiving It transmits data received from IED and RTU to substation and DAS. At the same time, it transmits data to IED and RTU receiving the control order and actually control them.

3. Operating data printer

This prints operating data such as event/report.

4. Standard time synchronizing device

This is a server where standard time is received from GPS to synchronize time with all the SA system devices in the substation.

5. Ethernet switch

This is used to connect devices such as IED and SA operating devices in the substation, monitoring/diagnosis devices and information connecting devices. This switch is composed of access switch connected with each devices and backborn switch connecting each access switches.

6. SA monitoring and diagnosis device

It is available to monitor and diagnose operating information with communication regulations as defined in IEC 61850 standards. All the data transmitted between SA operating device and IED are saved. Accessibility is granted through web interface. Network status, monitoring status of report and GOOSE data are shown on the screen. Re-saving is available by filtering saved data upon preferred time / device.

7. Panel configuring information

This device is comprised of SA system part (main/backup, E/S) including the information connecting device and SA Ethernet switch part.

Key Functions and Features

-

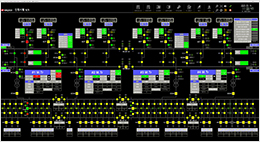

1. HMI Viewer

- Monitor facility/monitor measurement on a real-time basis

1. HMI Viewer

- Monitor facility/monitor measurement on a real-time basis

- Perform the order to control the device

-

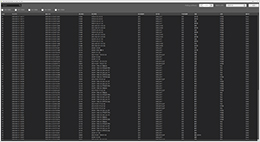

2. HMI Data Viewer

- Indicate events occurring in IED/RTU on a real-time basis

2. HMI Data Viewer

- Indicate events occurring in IED/RTU on a real-time basis

- Indicate monitoring/measuring point information of DB

-

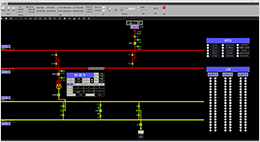

3. HMI Graphic Builder

- Add/delete symbols on the single line diagram indicated in HMI viewer

3. HMI Graphic Builder

- Add/delete symbols on the single line diagram indicated in HMI viewer

- Edit features

- Edit graphic tabular -

4. Information connecting device

- Convert IEC 61850 to DNP communication

4. Information connecting device

- Convert IEC 61850 to DNP communication

- Communicate with main devices with DNP communication

- Communicate with IED/RTU with IEC 61850 and DNP communication

- Dualize with main/backup

-

5. Engineering Tool

- Setup monitoring/controlling/measuring points

5. Engineering Tool

- Setup monitoring/controlling/measuring points

- Setup point features

- Save setup history DB -

6. IEC61850 Client

- Manage IED access

6. IEC61850 Client

- Manage IED access

- Collect/control IED data

- IEC 61850 communication protocol -

7. DNP Protocol

- Manage RTU access

7. DNP Protocol

- Manage RTU access

- Collect/control RTU data

- DNP communication protocol -

8. Monitoring/diagnosis device

- Monitor and diagnose IEC 61850

8. Monitoring/diagnosis device

- Monitor and diagnose IEC 61850

- Analyze wireshark-based IEC 61850

- Save and extract PCAP files

CEO : LEE DONG RYUL

CEO : LEE DONG RYUL